The manufacturing process adopts world leading production technology high quality production process and the supply chain spreads all over the world.

Photovoltaic processing solar panel manufacturing.

Photovoltaic cells make electricity from sunlight.

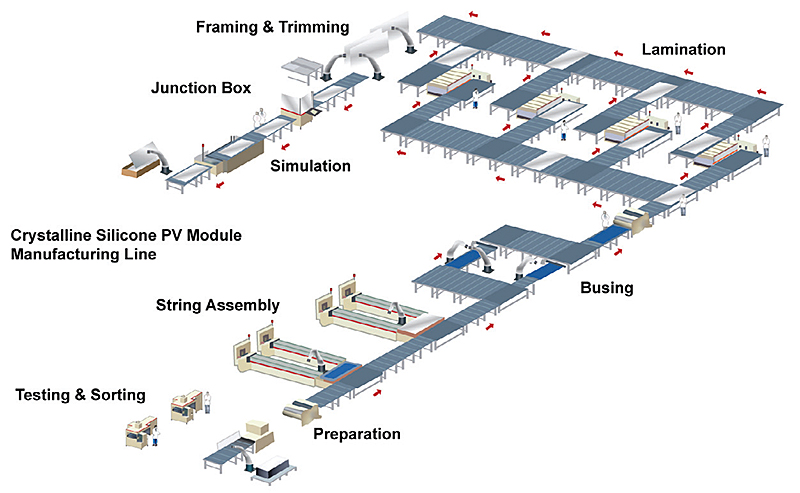

Today the standard practice includes the construction of production lines that can handle the entire solar module manifacturing process.

Are sunrun and tesla.

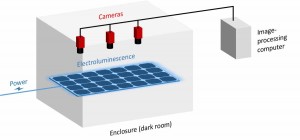

The next step in the solar panel manufacturing process is lamination.

The production of crystalline solar modules.

Just as solar installation is seasonal panel manufacturing flows the same.

As one of the world s leading solar pv manufacturers we have manufacturing facilities throughout the country including baoding hainan tianjin and hengshui.

We ll look at the manufacturing process for most common panels photovoltaic or pv.

While most solar panel manufacturers offer a ten year materials warranty rec provides a maximum of 20 year warranty against any defects in their solar panels.

Solar panel manufacturing process after having produced the solar cells and placed the electrical contacts between the cells they are then wired and subsequently arrayed.

Learn more about the components and the process of manufacturing a solar panel.

The top 3 solar manufacturers currently the top 3 solar manufacturers in the world are jinkosolar ja solar and trina solar respectively determined by market share among panel manufacturing companies.

To make solar cells the raw materials silicon dioxide of either quartzite gravel or crushed quartz are first placed into an electric arc furnace where a carbon arc is applied to release the the products are carbon dioxide and molten silicon.

Assemblies of photovoltaic cells are used to make solar modules which generate electrical power from sunlight as distinguished from a solar thermal module or solar hot water panel the electrical energy generated from solar modules colloquially referred to as solar power is an example of solar energy.

The biggest solar installation companies in the u s.

A manufacturer using its own facility will have busy times and down times but it is paying for that building the whole year.

The solar module manifacturing process is performed at an industrial level by special machines which assemble the various parts semi automaticly.

Here s how a solar panel is put together to do just that on your rooftop day after day.

Basically they do this by enabling light particles from the sun to knock electrons from atoms in the pv cells.

During lay up solar cells are stringed and placed between sheets of eva.

There are 3 types of solar panels available on the market.